NEW PRODUCT

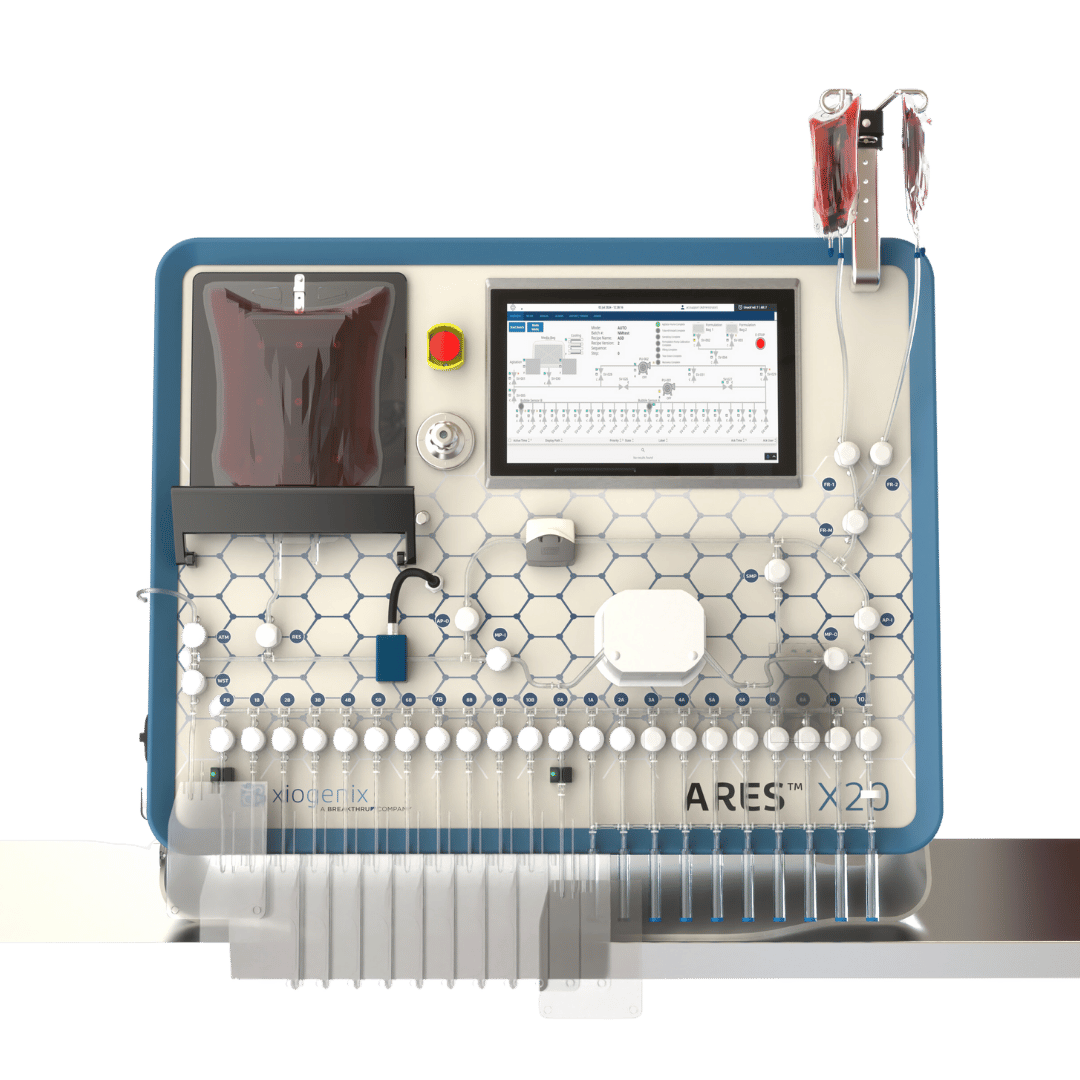

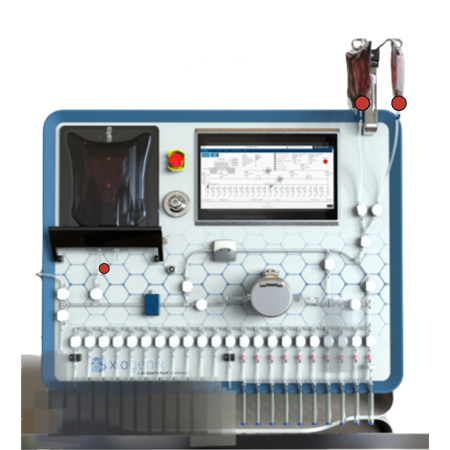

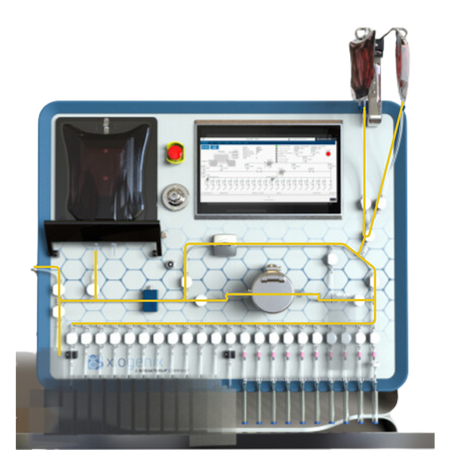

ARES™ X20+ Fill & Finish System

Compact, High-Throughput Fill & Finish

Compact, High-Throughput Fill & Finish

Cooling & Agitation

Cooling & Agitation

Fills Bags & Vials Within Single Batch

Fills Bags & Vials Within Single Batch

Closed System, Benchtop Design

Closed System, Benchtop Design

Compact, High-Throughput Fill & Finish

Compact, High-Throughput Fill & Finish

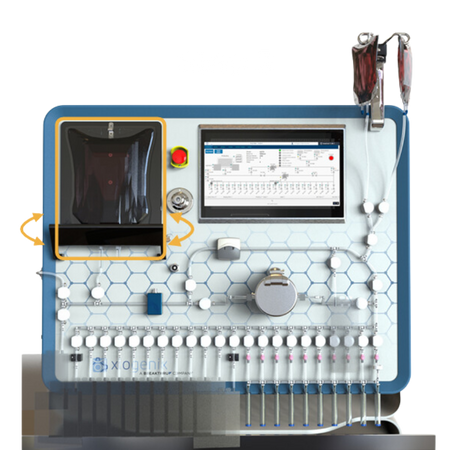

Cooling & Agitation

Cooling & Agitation

Fills Bags & Vials Within Single Batch

Fills Bags & Vials Within Single Batch

Closed System, Benchtop Design

Closed System, Benchtop Design

ARES™ X20+

Advanced Features

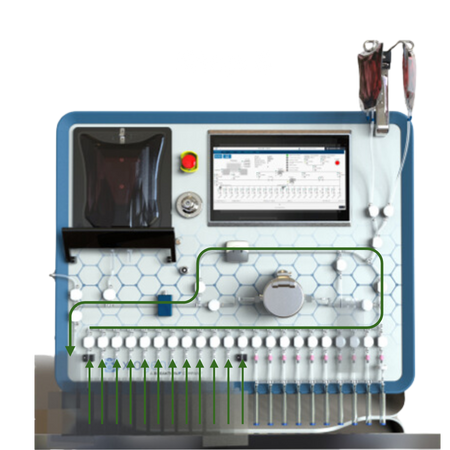

Automated Cooling & Agitation

Ensures precise temperature control and homogenization of the source material.

Formulation Flexibility

Weld up to two different media materials, such as cryoprotectant or buffer solution, to automate formulation into the source bag.

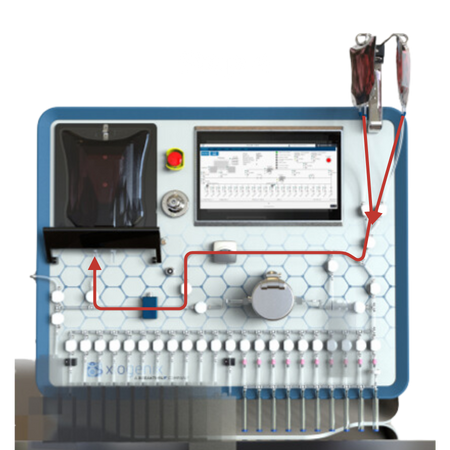

Air Evacuation

Minimizes residual air by removing air before the filling sequence.

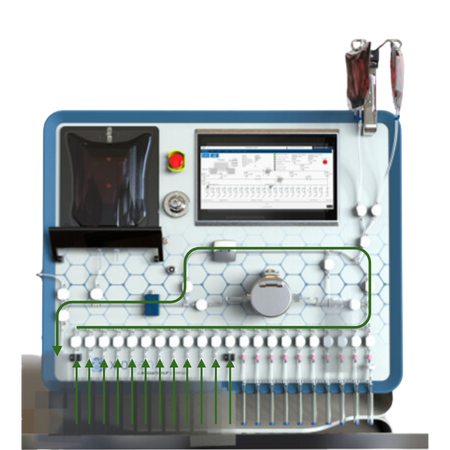

Efficient Serial Filling

Fills one container at a time across 20 slots, with an extended configuration option to increase capacity beyond 20 containers.

Fast Filling Process

Designed to minimize cryoprotectant contact time by increasing the efficiency of the formulation and final filling processes, capable of completing the entire process in under 5 minutes.

Recoverable Prime Volume

Automated purging feature ensures that all fluid within the lines (approx. 17ml) is recoverable.

Air Management

Semi-automated modes for removing excess air and burping bags post-fill. Automated and semiautomated options for removing air before and after a filling sequence.

ARES™ X20+

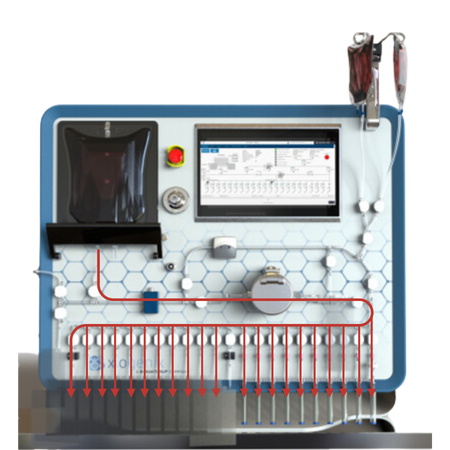

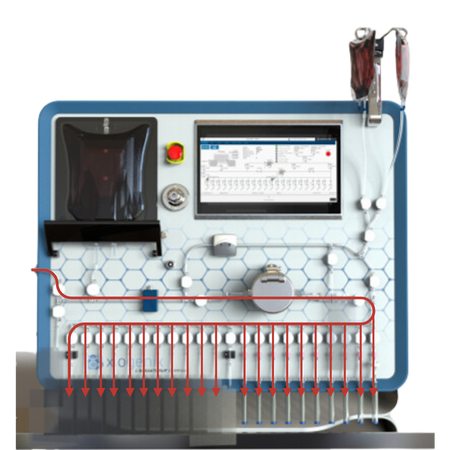

Process Flow

Weld Source Material and Formulation Media:

Securely weld the source material and formulation media to the manifold.

Setup the Manifold:

Attach the manifold to the system.

Cooling & Agitation:

Mixing of the source bag to ensure homogeneity while simultaneously cooling the bag.

Automated Formulation:

The system automates the formulation of media into the source material.

Air Evacuation:

The system has the ability to remove air from bags in an automated fashion for the distribution into the FDP containers.

Fill Sequence:

The source material is serially distributed into the FDP containers.

Post Fill Purge Sequence:

The system automatically purges the tubing to recover product, minimizing waste.

Post Fill Air Management:

If required, system has the capability to remove air following the fill sequence.

Connect with our Cell & Gene Therapy Team

Josh Jendusa

Director of Programs

"Success is not final, failure is not fatal: It is the courage to continue that counts." ~ Winston Churchill

Allie Schroeder

Director of Sales & Marketing

Disrupt. Create. Advance.® — Engineering Solutions for the Pharmaceutical Industry.

CONNECT WITH US

IMPORTANT LINKS

About

Cell & Gene Therapy

Tissue Banking

Services

News

Connect

Careers

LOCATIONS

United States

W160 S6550 Commerce Drive

Muskego, WI 53150

European Demonstration Office

46 Energieweg

Nijmegen 6441CX NL

Copyright 2025 Xiogenix. All rights reserved.